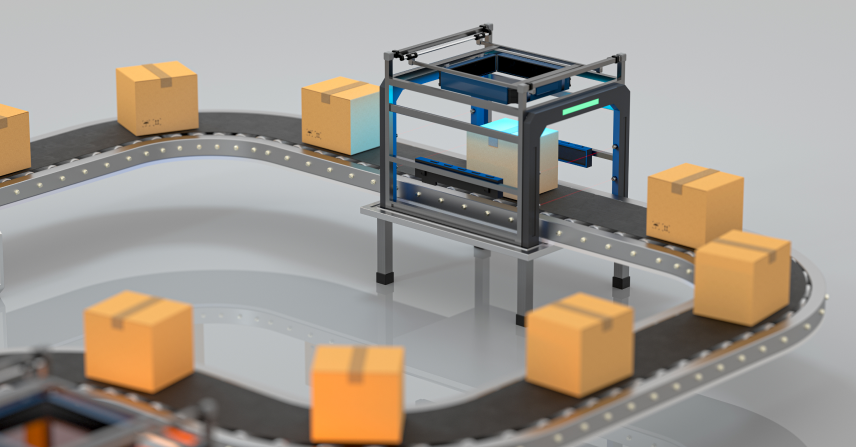

Industrial automation is the trend of widely using automatic control and adjustment devices in industrial production to replace manual operation of machines and machine systems for processing and production. Under the conditions of industrial production automation, humans only indirectly take care of and supervise machines for production.

Industrial automation technology is a comprehensive high-tech that applies control theory, instrumentation, computers, and other information technologies to detect, control, optimize, schedule, manage, and make decisions in industrial production processes, achieving the goals of rapidly increasing production, improving quality, reducing consumption, and ensuring safety. It includes three major parts: industrial automation software, hardware, and systems. Industrial automation rock reed technology, as one of the most important technologies in modern manufacturing in the 20th century, mainly solves the problems of production efficiency and consistency. Both high-speed mass manufacturing enterprises and enterprises pursuing flexibility, adaptability, and customization must rely on the application of automation technology. The automation system itself does not directly create benefits, but it plays a significant role in improving the production process of enterprises:

(1) Improve the safety of the production process;

(2) Improve production efficiency;

(3) Improve product quality;

(4) Reduce the consumption of raw materials and energy in the production process.

According to authoritative consulting agencies, the ratio of investment in automation systems to improvement in enterprise efficiency is approximately 1:4 to 1:6 per mu of jujube production. Especially in capital intensive enterprises, automation systems account for less than 10% of the total equipment investment, playing a role of "four taels of gold". The traditional industrial automation system, also known as mechatronics system, mainly controls equipment and production processes. It consists of hardware elements such as mechanical body, power part, testing and sensing part, execution mechanism, driving part, control and signal processing unit, interface, etc., which are guided by purposeful information flow of software programs and electronic circuit logic to coordinate, organically integrate and form orderly and regular movement of matter and energy, thus forming an industrial automation system or product.

In the field of industrial automation, traditional control systems have gone through the development process of base based pneumatic instrument control systems, electric unit combination analog instrument control systems, centralized digital control systems, and distributed control systems DCS.

With the development of control technology, computer, communication, network and other technologies, the field of information exchange and communication is rapidly covering various levels from the on-site equipment layer of factories to control and management. Industrial control machine system generally refers to the general term for automation technology tools (including automatic measuring instruments and control devices) that measure and control industrial production processes, their electromechanical equipment, and process equipment. Today, the simplest understanding of automation has also shifted to using generalized machines (including computers) to partially, completely, or surpass human physical strength.