As the core component of new energy vehicles, the production and assembly process of power batteries is crucial for the performance and quality of the entire vehicle. With the advancement of technology and the rapid development of intelligent manufacturing, the automatic assembly line for power battery packs has become a hot topic in the industry.

1、 The advantages of automatic assembly line for power battery pack assembly line

Improving production efficiency: The automated line system greatly improves the assembly efficiency of power battery packs through highly automated equipment and process flow. Compared to traditional manual assembly methods, automatic line systems can achieve faster production speeds and higher output, thereby meeting the strong demand for new energy vehicles in the market.

Ensure product quality: The automatic line system adopts precision mechanical equipment and advanced control system, which can ensure the assembly accuracy and consistency of the power battery pack. At the same time, the automated production line system can effectively eliminate unqualified products through strict quality inspection and screening procedures, ensuring that product quality reaches a high level.

Reduce production costs: Although the initial investment cost of the automated production line system is high, in the long run, it can effectively reduce production costs by improving production efficiency and reducing labor costs. In addition, the automated production line system can also reduce losses and waste caused by human operational errors, further improving production efficiency.

Strong adaptability: The automatic line system can be flexibly adjusted according to different models and specifications of power battery packs to meet the diverse needs of the market. At the same time, the automated production line system can seamlessly integrate with other production equipment and systems, achieving the intelligence and automation of the production line.

2、 Technical principle of automatic assembly line for power battery pack assembly line

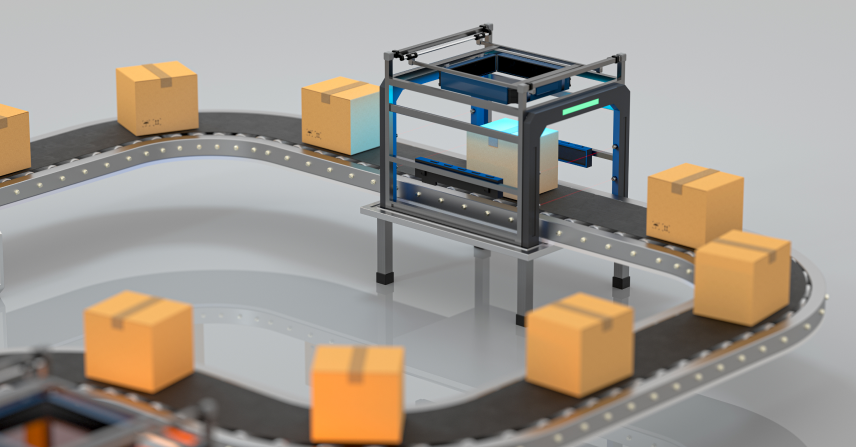

The automatic assembly line for power battery pack mainly consists of conveying system, assembly system, detection system, and control system. Among them, the conveying system is responsible for transporting the power battery pack to be assembled to the designated location; The assembly system completes the assembly of the power battery pack through equipment such as robotic arms and laser welding; The detection system is responsible for conducting a comprehensive inspection of the assembled power battery pack to ensure that its quality and performance meet the requirements; The control system is responsible for coordinating and controlling the entire automatic line system, ensuring the coordinated operation between various systems.

In actual operation, the control system will issue instructions to various systems based on preset production plans and process parameters. The conveying system will transport the power battery pack to the designated location according to the instructions, and the assembly system will complete the assembly work of the power battery pack according to the instructions. At the same time, the detection system will conduct a comprehensive inspection of the assembled power battery pack and provide feedback to the control system. If the test results are not qualified, the control system will instruct the assembly system to rework or remove the unqualified products; If the test results are qualified, the power battery pack will be transported to the next process or finished product area.

3、 Application scenarios of automatic assembly line for power battery pack assembly line

The automatic assembly line for power battery packs is widely used in the production and manufacturing process of power batteries for new energy vehicles. According to different production needs and scenarios, the automated production line system can be flexibly configured and adjusted. For example, in large-scale power battery production bases, highly automated assembly line systems can be used to achieve large-scale and efficient production; In small-scale power battery production enterprises, more flexible and compact assembly line systems can be adopted to meet the diverse needs of the market.

In addition, with the continuous expansion of the new energy vehicle market and advances in technology, the automatic assembly line for power battery packs will have even broader application prospects. For example, in the future field of power battery recycling and reuse, automated line systems can achieve efficient dismantling and recycling of waste power batteries; In terms of customized production of power battery packs, the automatic line system can flexibly adjust and produce according to customers' personalized needs.

4、 How to choose the appropriate power battery pack assembly line automatic line system

When choosing a suitable power battery pack assembly line automatic line system, the following aspects need to be considered:

Production requirements: Firstly, it is necessary to clarify one's own production needs and goals, including production scale, product models and specifications, production speed, etc. These factors will directly affect the selection and configuration of automated line systems.

Technical proficiency: Choose an automated production line system that is mature, stable, and reliable in technology. The technical level of suppliers can be evaluated by examining their technical strength, product performance, and market reputation.

Cost control: When choosing an automated line system, it is necessary to comprehensively consider factors such as initial investment costs, operating costs, and maintenance costs. To ensure that the selected system is economically reasonable and feasible.

Service support: Excellent suppliers should be able to provide comprehensive service support, including equipment installation and commissioning, operation training, maintenance, etc. This will help ensure the smooth operation and efficient production of the automated line system.

By considering the above factors comprehensively, choosing a suitable power battery pack assembly line automatic line system will bring revolutionary changes and improvements to the production and manufacturing of enterprises.

Summary:

As an important component of intelligent manufacturing, the automatic assembly line for power battery packs is of great significance in improving production efficiency, ensuring product quality, and reducing production costs. With the continuous expansion of the new energy vehicle market and advances in technology, automatic line systems will become an essential choice for power battery production enterprises. When choosing a suitable automatic line system, enterprises need to comprehensively consider factors such as their own needs, technological level, cost control, and service support to ensure that the selected system can bring great value and benefits to the enterprise.